A collimator is a device used to transform the divergent light or other radiation from a point light source into a parallel beam, and also is an absorber device used to limit X-rays, gamma rays, or nuclear particle beams to the size and angular spread required for a specific application. Normally, special measurements in spectroscopy and geometric and physical optics require this kind of light collimation.

For reasons of patient dose and image quality, X-ray collimation for radiography and fluoroscopy projection imaging is important. Actively collimating the volume of interest will reduce the overall integrated dose to the patient, thereby minimizing the risk of radiation. Less radiation will result in less X-ray scattering incident on the detector. This leads to improved object contrast and image quality.

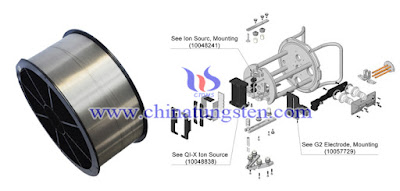

In a linear accelerator (linac), the main collimator may be made of depleted uranium because the density of this material is approximately 1.6 times that of lead. The secondary electric collimator can better define the beam shape and is made of lead or tungsten. The multi-leaf collimator (MLC), which is now widely used in medical linear accelerators, consists of two thin tungsten "leaf" collimator groups, each group consisting of 40 to 80 leaves composition.

As depleted uranium and lead materials are not easy to completely eliminated by the body after entering the human body, and will damage the internal organs, tungsten metal is the most popular materials for this device now. Generally spreading, the higher density of the material, the better radiation protection. Why tungsten alloy collimator is more popular compared with pure tungsten collimator?

The density of tungsten metal is high, however, it is also easy to fragile during machining if you use powder metallurgy to produce, especially for complex collimator. Therefore, tungsten alloy, added with the element of nickel, copper or iron, help improve the problem. The alloy has high density, better processability and good anti-radiation, and thus most collimators are made of this material.

If you have any inquiry of tungsten collimator, please feel free to contact us:Email: sales@chinatungsten.com/sales@xiamentungsten.com

Tel.: +86 592 5129696/+86 592 5129595