A collimator, a device used to transform the diverging light or other radiation from a point light source into a parallel beam. Special measurements in spectroscopy and in geometric and physical optics require this kind of collimation.

The optical collimator consists of a tube. One end of the tube is a convex lens, and the other end is an adjustable aperture. The aperture is located in the focal plane of the lens. The radiation entering the aperture leaves the collimator as a parallel beam, so the image can be viewed without parallax.

The collimator may be a telescope with an aperture at the main focal length of the lens. The light from the light source is focused on the slit through another lens with a similar focal length, and the slit serves as the light-emitting object of the optical system.

In radiology, a collimator is a set of absorbers used to limit X-rays, gamma rays, or nuclear particle beams to the size and angular spread required for a particular application.

The typical manufacturing technology for this product is powder metallurgy + machining process. This process can take months and cost is very high. For complex parts, it is difficult to be processed with traditional method. Now that they can be 3D printed, the same collimators can be manufactured in 5 to 15 days with low costs.

Moreover, this process can allow for much finer detail in collimator designs, meaning that researchers have the capability to reduce leaks and shape a collimator in unique ways.

The 3D printed collimators could lead to a change in the way collimators are used. Currently, a single collimator is used for a single neutron scattering instrument. Now that collimators can be created quickly and inexpensively, they can be changed and used in different experiments, similar to the use of different sample environments for different experiments.

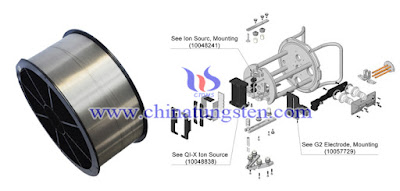

Chinatungsten Online is a professional manufacturer of tungsten and molybdenum. Kindly feel free to contact us if you have got the purchasing plan for 3D printed collimators.